Advanced Response through an Integrated Production System

Forged Steel ProductsWe offer the highest quality through integrated production.

We can respond to various customer needs through integrated manufacturing, from material procurement to cutting, forging, heat treatment, machining, testing and inspection, and shipping. We are also actively working to acquire qualifications, and to improve our high quality standards and our technologies to meet our customer’s needs.

Integrated Production Flow

【Forged Steel Products】

Material Management / Cutting

After cutting, assign a traceable number to everything, and manage the process up to the shipment.

Can be cut up to the maximum outside diameter of φ1000

Forging

We conduct forging with the optimal shape using our unique know-how.

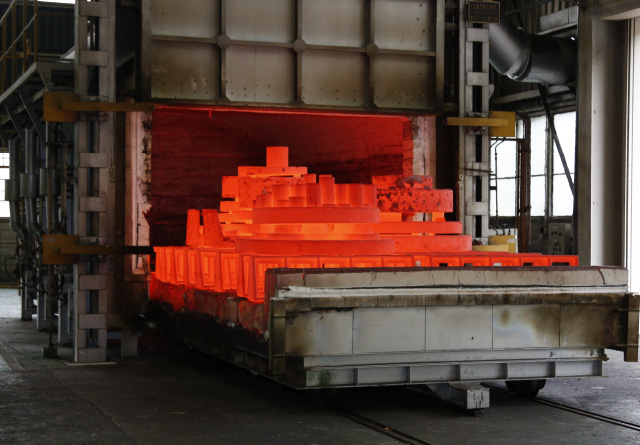

Heat Treatment

Heat treatment is performed under individual conditions.

Normalizing, normalizing and tempering, quenching and tempering, and solution treatment are supported.

Machining

We conduct machining based on the customer's drawings, and finish to the required shape and dimensions.

Machine Testing

We take test pieces in accordance with various material standards and the customer's specifications, and conduct machine testing.

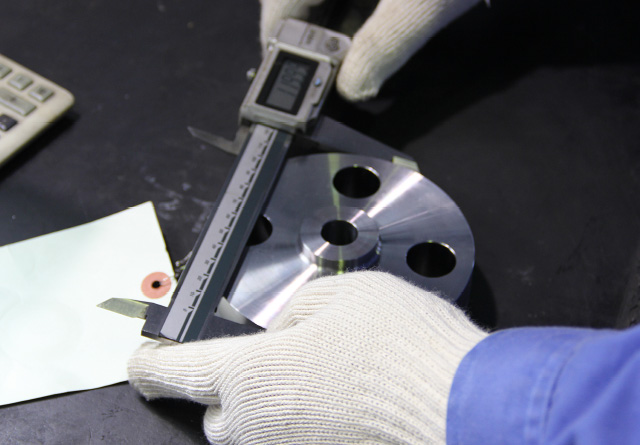

Product Inspection

We perform quality checks by dimension measurement, and non-destructive inspection.