OFFICE / WORKS

Ichikawa Works

This facility is engaged in the manufacture of a wide variety of forged steel products. Product quality is strictly controlled through consistent manufacturing comprising material cutting, forging, heat treatment, machining, and shipping. In addition, active efforts have been and continued to be made to achieve accreditations and meet customer needs through high levels of quality and technical improvements.

Forged Steel Products

Manufacturing Technology and Quality

History-proved achievements and trust relationship

By means of our technology cultivated over our 90-plus year history, we have delivered products with a high technical rating in a wide variety of fields, ranging from marine and a wide variety industrial machinery to nuclear applications.

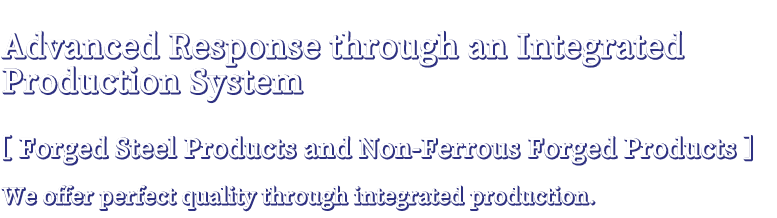

Advanced Response through an Integrated Production System

We manufacture highly reliable products through an integrated production management system from raw materials to forging, heat treatment, and machining, and a reliable quality management system.

By establishing a production management system, we can respond to various customer needs under the assurance of perfect quality of individual specification products and special specification products.

Wide Range of Supported Steels

Due to our unceasing pursuit of forging and machining techniques, we are capable of handling a wide range of steels.

List of Materials Handled

Forged Steel Products

| Standard | |||||

|---|---|---|---|---|---|

| JIS | ASTM(ASME) | ||||

| Carbon Steel |

|

|

|||

| Low Temperature Carbon Steel |

|

|

|||

| Alloy Steel |

|

|

|||

| Alloy Steel for Machine Structure |

|

|

|||

| High Carbon Chromium Bearing Steel |

|

|

|||

| Stainless Steel |

|

|

|||

| For Nuclear Power Plants |

|

|

|||

| Other Steels |

|

|

|||

Non-Ferrous Forged Products

| Standard | ||

|---|---|---|

| JIS | ASME | |

| Aluminum Alloy |

JIS H 4140 A5083 JIS H 4140 A6061 |

SB-247 5083 SB-247 6061 |

| Nickel Alloy |

NCF020 NW6022 NW0276 NCF600 NCF601 NCF625 NCF750 |

SB-473 UNS N08020 SB-564 UNS N06022 SB-564 UNS N10276 SB564 UNS N06600 SB564 UNS N06601 SB564 UNS N06625 SB-637 UNS N07750 |

We also handle a wide range of other materials.

Please feel free to contact us.

Certifications

List of Certifications

<JIC Quality Assurance>

■ ISO9001 accreditation

■ ISO14001 accreditation

■ Works authorized to indicate Japanese Industrial Standards accreditation according to JISB2220

<Pressure Equipment Directive>

■ PED2014/68/EU(HSBIL)

<Class Certification>

■ NK (Nippon Kaiji Kyokai) Forged Steel Products Approved Factory

■ NK (Nippon Kaiji Kyokai) Welding Pipe Flange Manufacturing Approved Factory

■ LR (Lloyd's Register of Shipping) Forging Products Approved Factory

■ DNV GL (Det Norske Veritas Germanischer Lloyd) Approved Factory for Forgings

■ KR (Korean Register of Shipping) Forgings Manufacturing Approved Factory

■ BV (Bureau Veritas) Forgings Manufacturing Approved Factory

■ ABS (American Bureau of Shipping) Approved Factory for Forgings

Equipment Introduction

Forging Press/Heat Treatment Equipment

Primary Equipment

| Category | Equipment Name | No. | Max Capacity |

|---|---|---|---|

| Forging | Hydraulic 1500 tons press | 1 | φ1600×1300H×5000kg |

| Hydraulic 1000 tons press | 1 | φ1100×800H×1000kg | |

| Hydraulic 500 tons press | 1 | φ700×500H×300kg | |

| 500kg air hammer | 1 | φ350×300H×45kg | |

| Cooperating company:φ4500×1500H×20000kg | |||

| Heat treatment | Dolly type LPG furnace (15 tons furnace) | 1 | 2700W×1500H×5000L |

| Dolly type LPG furnace (5 tons furnace) | 1 | 1800W×1500H×3000L | |

| Dolly type LPG furnace (2 tons furnace) | 1 | 1000W×800H×1500L | |

| Box type electric furnace (For test pieces) | 7 | ||

| Cooperating company:3300W×1000H×4500L | |||

| Quenching water tank | 1 | φ6000×3900H |

Cutting and Processing Equipment

Main Lath

| Category | Equipment Name | No. | Max Capacity |

|---|---|---|---|

| Cutting | H1000 II automatic sawing machine | 1 | φ1000 |

| PCSAW700 automatic sawing machine | 1 | φ700 | |

| PCSA430 type automatic sawing machine | 1 | φ430 | |

| Other sawing machine | 8 | ||

| Machining | Long lathe | 2 | φ800×4000L |

| Lathe | 2 | φ1200 | |

| Five-sided processing machine | 2 | 4000L×2000W×1800H(up to 20 tons) | |

| CNC vertical lathe | 10 | φ2500×1300H | |

| Ordinary lathe | 4 | φ600×300L | |

| CNC lathe | 8 | φ350×950L | |

| Vertical machining center | 3 | 1250L×700W×650H | |

| Radial drilling machine (with automatic indexing device) | 4 | φ3000×1700L | |

| CNC drilling machine | 3 | φ1500×310H | |

| Drilling machine | 2 | φ600×300H | |

| Boring facing-and-drilling machine | 2 | 2000L×1800W×2000H |

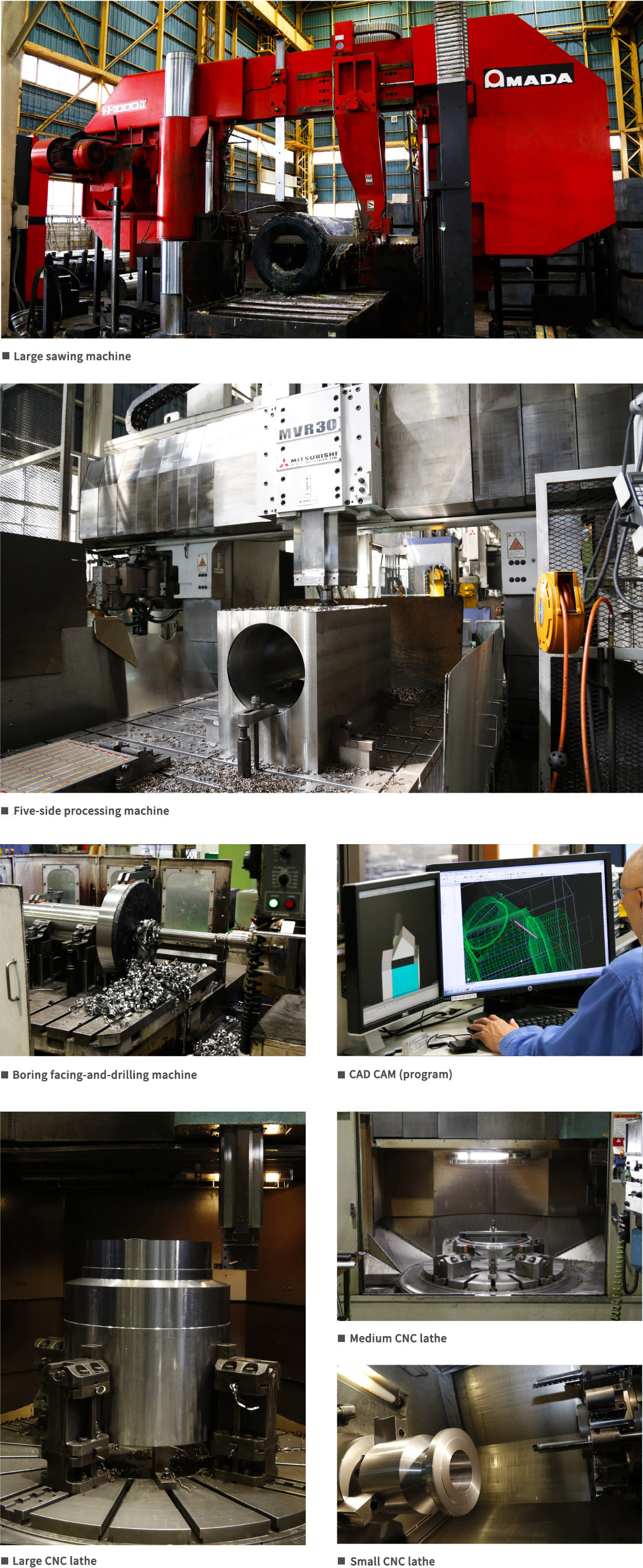

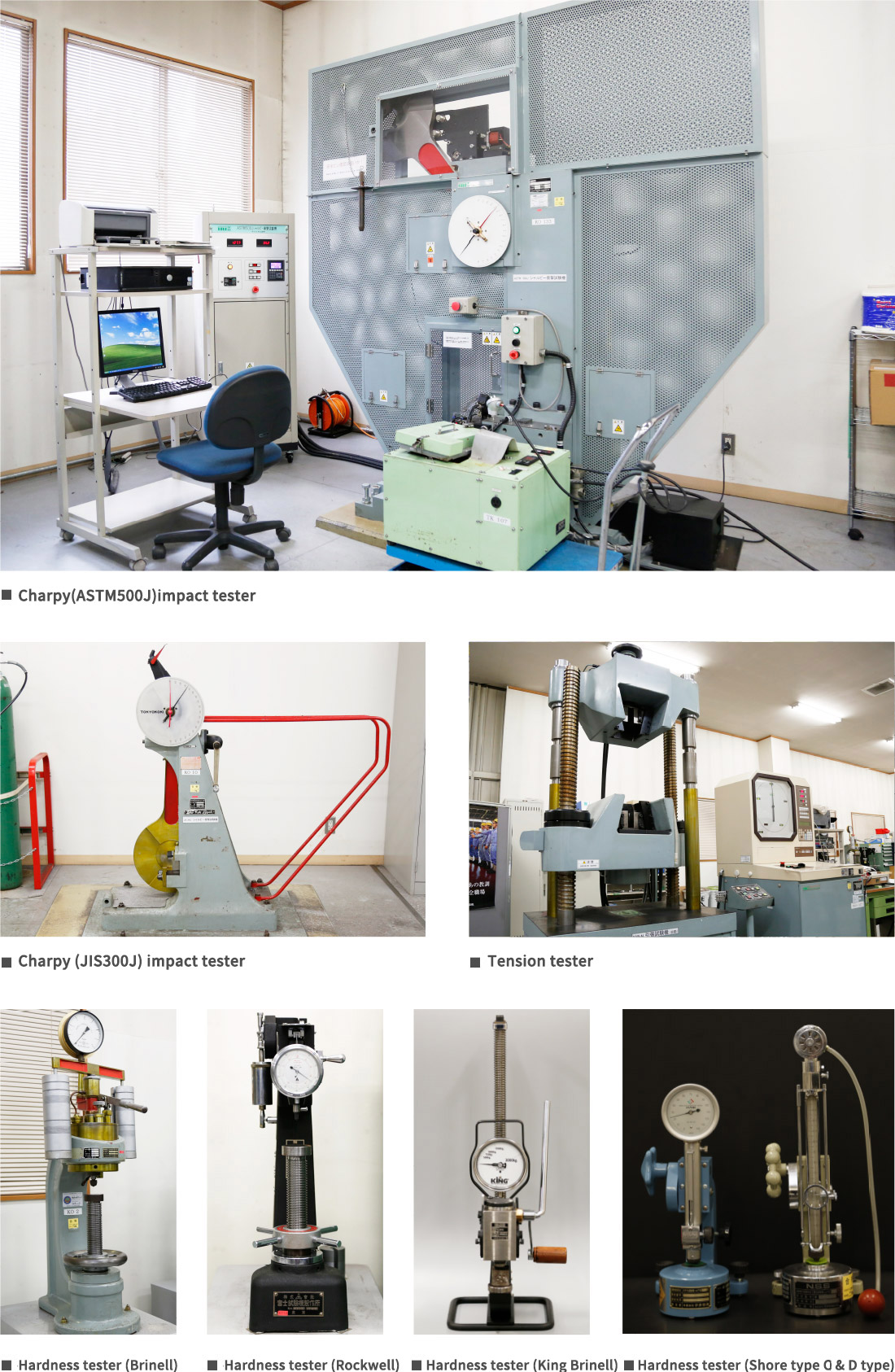

Testing and Inspection Equipment

| Nondestructive testing | Qualification |

|---|---|

| Ultrasonic Test | JIS Z 2305 UT level 2 (NDI UT-2) |

| Penetration Test | JIS Z 2305 PT Level 2 (NDI PT-2) |

| Magnetic-Particle Test | JIS Z 2305 MT Level 2 (NDI MT-2) |

Address & Access

Phone: +81-790-28-0590

Fax: +81-790-28-1140

・JR-West Bantan Line: Ten minutes on foot from Tsurui Station (Thirty minutes from Himeji)

・Bantan Renraku Road: Seven minutes by car from Ichikawa Kita Ramp or ten minutes by car from Ichikawa Minami Ramp